Constructions for the offshore sector based on sea water

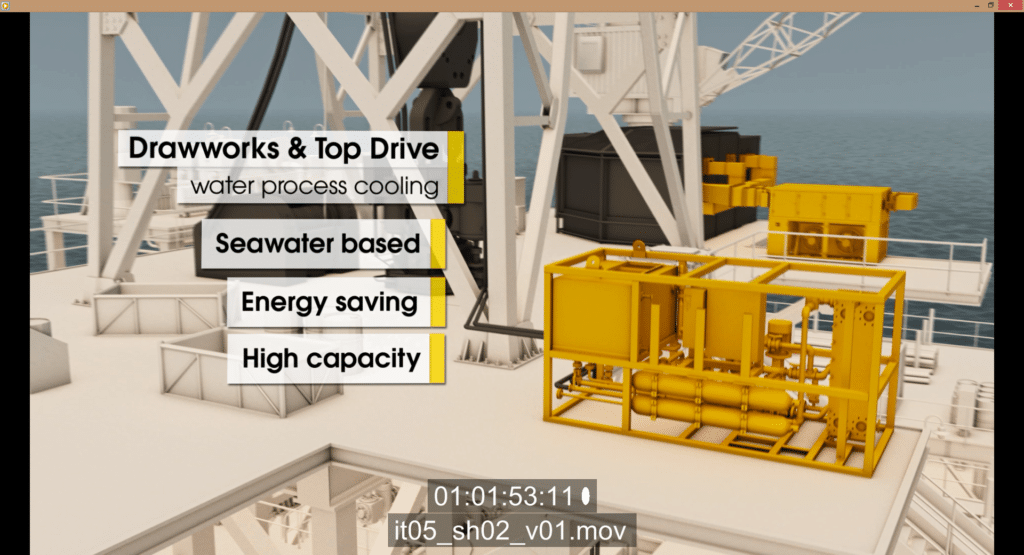

Find out about the constructions for the offshore sector. The engineers form Polish-Norwegian ITEK PL company has designed the sea water based cooling unit to provide the top drive drilling motors with sufficient cooling and the Base Group made metal constructions to new product.

The main components are reservoir, filling pump, accumulator, circulating pump and heat exchanger. The cooling unit will circulate a glycol/water mix in a closed loop system through pipes and loop hoses in the derrick. The pressure will be regulated by draining or filling the accumulator. The flow is monitored by a sensor and regulated by a frequency driven circulating pump.

Constructions for the offshore sector

Designed system has to enable to keep some boundary conditions:

- The demanded maximum overpressure before top drive should not exceed

- The overpressure in every point of system during top drive motors’ operation should be positive

- The highest overpressure in any point of system should not exceed maximum value Top drive is moving with vertical speed

As water with glycol generates high pressure drop in pipelines and top drive is changing its altitude, there is no possibility to keep all above boundary conditions without dynamic change of pressure in system.

The changes of pressure in system will be generated by changes of pressure on the liquid side of the accumulator. The accumulator is equipped with elastic bag with some gas amount inside. The pressure in the accumulator is a function of gas / water volume in vessel. The mass of gas is kept constant but the volume and pressure is changed by changing the volume of water inside. The changing of water volume is generated by pumping it into the vessel or releasing it to outside. This will make the gas more or less compressed, and will generate pressure change.

During operation – to increase the pressure we have to pump water into the accumulator = to compress the gas, as long as it achieves ordered pressure. To decrease the pressure we have to release some water from the accumulator – as long as the uncompressed gas achieves required pressure. To be able to control this, changes of water volume in the accumulator shouldn’t be too small.