Welding of steel structures for power industry using the supervisory system

Base Group is the first manufacturing company in Poland to have successfully launched an electronic system for welding process management. Our system oversees welding of steel structures for power industry, offshore construction welding, structures for customers from the railway industry and welding of structures for the chemical industry. This is actually our next step into Industry 4.0.

The electronic system for welding process management is a solution to be used from the first stage of planning the welding work, through coordination of welding the structures, up to the final stage of project reporting.

At the stage of the work planning, after our welding engineers have entered the welding process qualification data, the system prepares the welding process instructions. The system also supports assigning work to welders. The software checks whether a particular welder holds the licence necessary to weld a given structure. If not – the program does not allow assigning such a welder to the task.

This software covers all welding machines available at Base Group. By connecting each device to the server, we are able to control the parameters at each station. Automatic parameter registration provides you means of control and enables you to keep track of your work. In the event that parameters are exceeded, information about irregularities appears immediately on the welding engineer’s monitor. In addition, at the station, the device connected to the welding machine displays a red error message, whereas welding according to parameters is indicated by a message displayed in green. For us, the information about the deviation from the guidelines is significant because it enables us to react quickly and so avoid the costs associated with rectification.

Data are collected and stored in one place. This fact helps at the last stage of the structure manufacture. Program can make to generate a reliable and error-free welding documentation for the customer in a short time. Well-prepared documentation is particularly important for clients from the power, offshore, railway and chemical industries, for whom we manufacture specialized structures and industrial equipment.

Since we have implemented the electronic system for management of the welding process, the following have been completed with its support:

– flanges for high voltage line insulators,

– supporting structures for high voltage insulators,

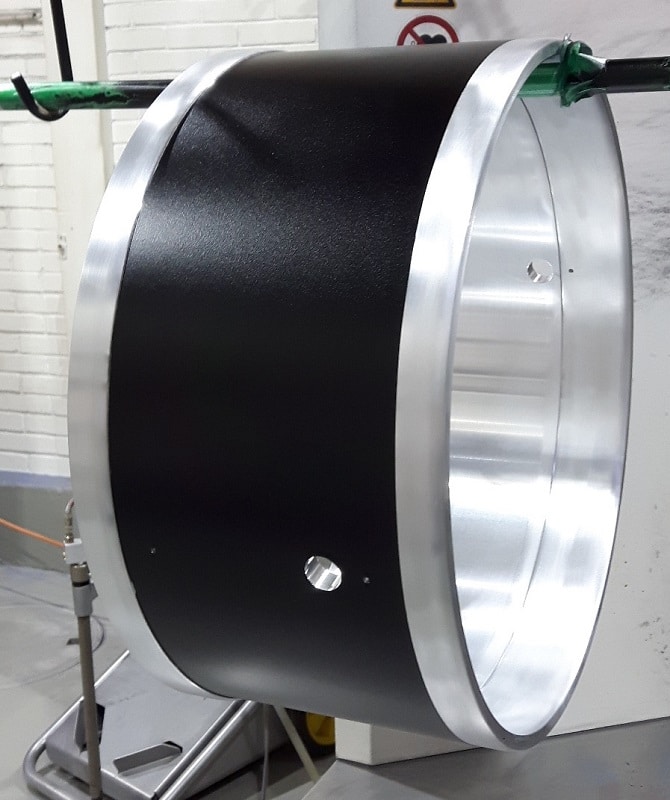

– frames for fans of engine cooling systems,

– foundations for marine engines,

– refrigerating container for locomotives,

– tanks used in the wastewater treatment process,

– tanks used in the production of pharmaceutical products,

– components of large hall constructions.

By way of a summary, we can provide the following advantages of the electronic system for management of the welding process:

- supervision over the welding process,

- constant monitoring of compliance with WPS (welding parameters),

- better resource management,

- elimination of quality errors,

- meeting high customer requirements,

- independent reporting of results,

- less time for preparation of documentation.

Thanks to the implementation of the electronic system for management of the welding process, we fully control the quality and main parameters of the process. We control of welding structures for power, offshore, railway or chemical industries, which is of great importance to our clients.

We invite you to watch the movie (video is available with subtitles in English) we’re talking about manufacturing of metal constructions for industries using the Impuls and WeldEye system – welding using the Impuls and Weldeye system