The measurement laboratory aids to manufacture welded metal structures

In line with its strategy, the Base Group company carries out long-term investments in connection with the expansion of its machine park. The aim of the company is to manufacture welded metal structures at the highest quality level. Knowledge, experience of the quality control department employees and measurement capabilities are the guarantee of the quality of our services. The measurement laboratory of the Base Group enables us to carry out tests with a wide range of quality requirements. Over the years, the laboratory has been equipped

with control and measurement tools, i.e:

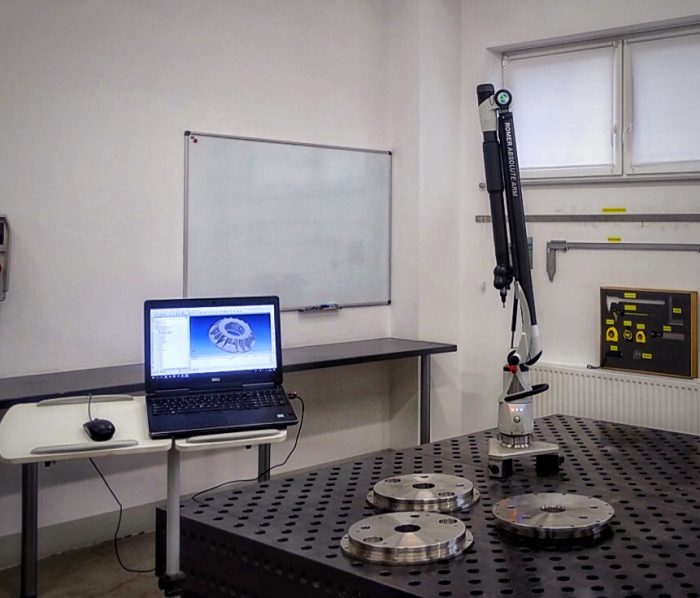

- Measuring arm Romer Absolute ARM RA-7530

- OLYMPUS Optical Spectrometer

- Roughness meter

- Paint coating thickness gauges

- Digital handheld hardness tester

- Electronic spirit level

- Measuring table SIEGMUND

The Base Group has recently acquired Hexagon’s Measurement Arm. A new series of portable devices that allow metrology to be introduced directly into the production environment. The Romer Absolute arm with a measuring range of 3m allows the arm to be adjusted so that the maximum range is 9m without losing accuracy. Thanks to the modern carbon fibre construction, the device maintains its strength and thermal stability in all environmental conditions, regardless of the environment in the hall. The Absolute ASrm measuring arm joint features absolute encoders that eliminate the need to initialize

and heat the device. The modular construction of the joint has configurable shapes and sizes of the handle and the display so that the user can control the measurement. Laser scanner is the key to technologically advanced 3D scanning and digitalization.

These advantages of the Measuring Arm provide the Base Group with advanced metrology measurements. Modern technologies increase productivity and improve production processes.